The reasonable layout of electronic components on a PCB board is a crucial factor in reducing soldering defects.

Components should avoid areas with very large deflection values and high internal stresses,

and the layout should be as symmetrical as possible.

In order to maximize the use of circuit board space, I believe that many design partners will try to place the components

against the edge of the board,but in fact, this practice will bring great difficulty to production and PCBA assembly,

and even lead to soldering assembly failed!

Today, let's talk to you in detail about the layout of components on board edge

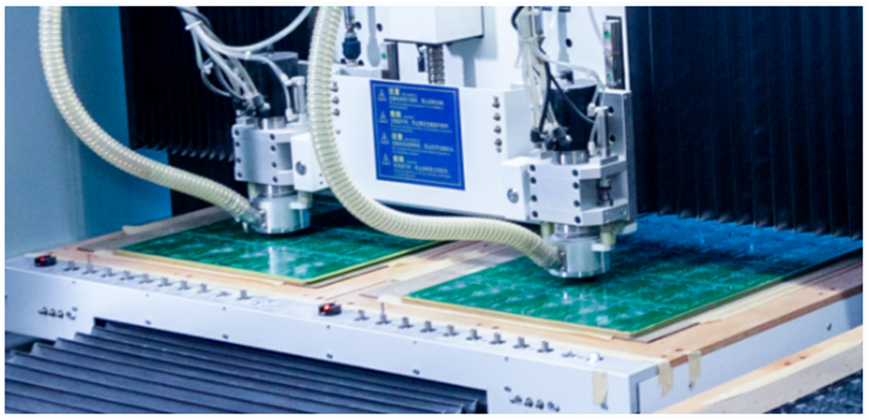

1. Routing in profile process

The component is placed too close to the edge of the board, and the pad of the component will be milled off when routing process,

and the distance between the general pad and the edge needs to be greater than 0.2mm,

otherwise the pad of the board edge will be milled off and the components cannot be soldered during assembly.

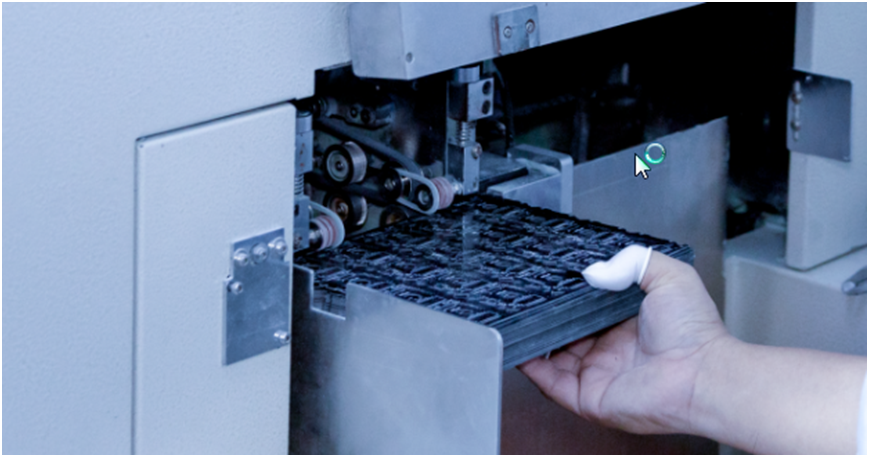

2. V-CUT in profile process

If the board edge is V-CUT in a panel, the components need to be farther from the board side,

because the V-CUT knife passes through the middle of the board, and the general component is more than 0.4mm

from the board edge of the V-CUT,

otherwise the V-CUT knife will hurt the pad, resulting in the components cannot be soldered.

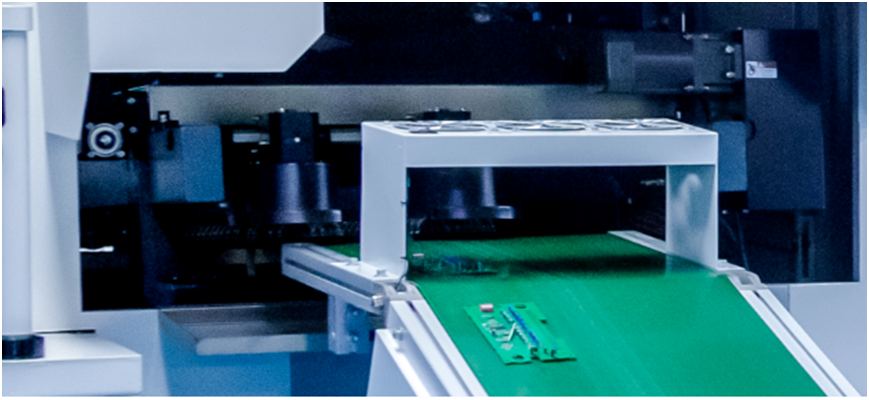

3. Component interference devices

When design, component layouts that are too close to the edge of the board can interfere with the operation of

automated assembly equipment, such as wave soldering or reflow soldering machines, when assembling components.

4. The device crashes components

The closer the component is to the board side, the greater the potential interference of the component to

the assembly equipment, such as large electrolytic capacitors and other components, because the electrolytic capacitor

components are relatively high, such components should be placed further away from the edge of the board than other components.

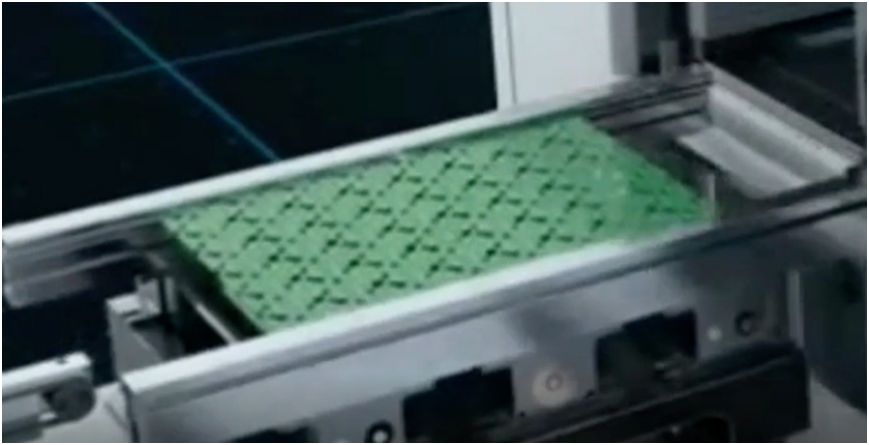

5. Breaking boards damages the component

After the product is assembled, the imposition product needs to be deboarded, and during separation,

components that are too close to the edge may be damaged, which may be intermittent and difficult to detect and debug.